“MP Filtri’s LPA3 Particle Counters increase the efficiency of our operation, save our engineers valuable time and most importantly, enhance and increase the value of service Hydracare offers to our customers.”

Customer Profile

Based in Wimborne, Dorset, Hydracare is the leading supplier of oil products and support services to the plastic moulding industry. They have more than 25 years’ experience in testing, monitoring, and maintaining hydraulic systems to ensure the best in productivity and enhance the lifespan of complex machinery.

The cornerstone of their business success is providing fast and accurate data on oil cleanliness – ensuring ISO standards are met and providing early warning of any potential particle contamination issues.

The challenge

Speed and accuracy are vital to Hydracare’s customers. The company had previously relied on sending samples to independent laboratories – ensuring precise results but taking up valuable time.

To speed up the process Hydracare tested a number of rival particle counters – but with varying results. What they needed was a highly accurate, easy to use portable particle counter with fast sampling times and outstanding repeatability.

The solution

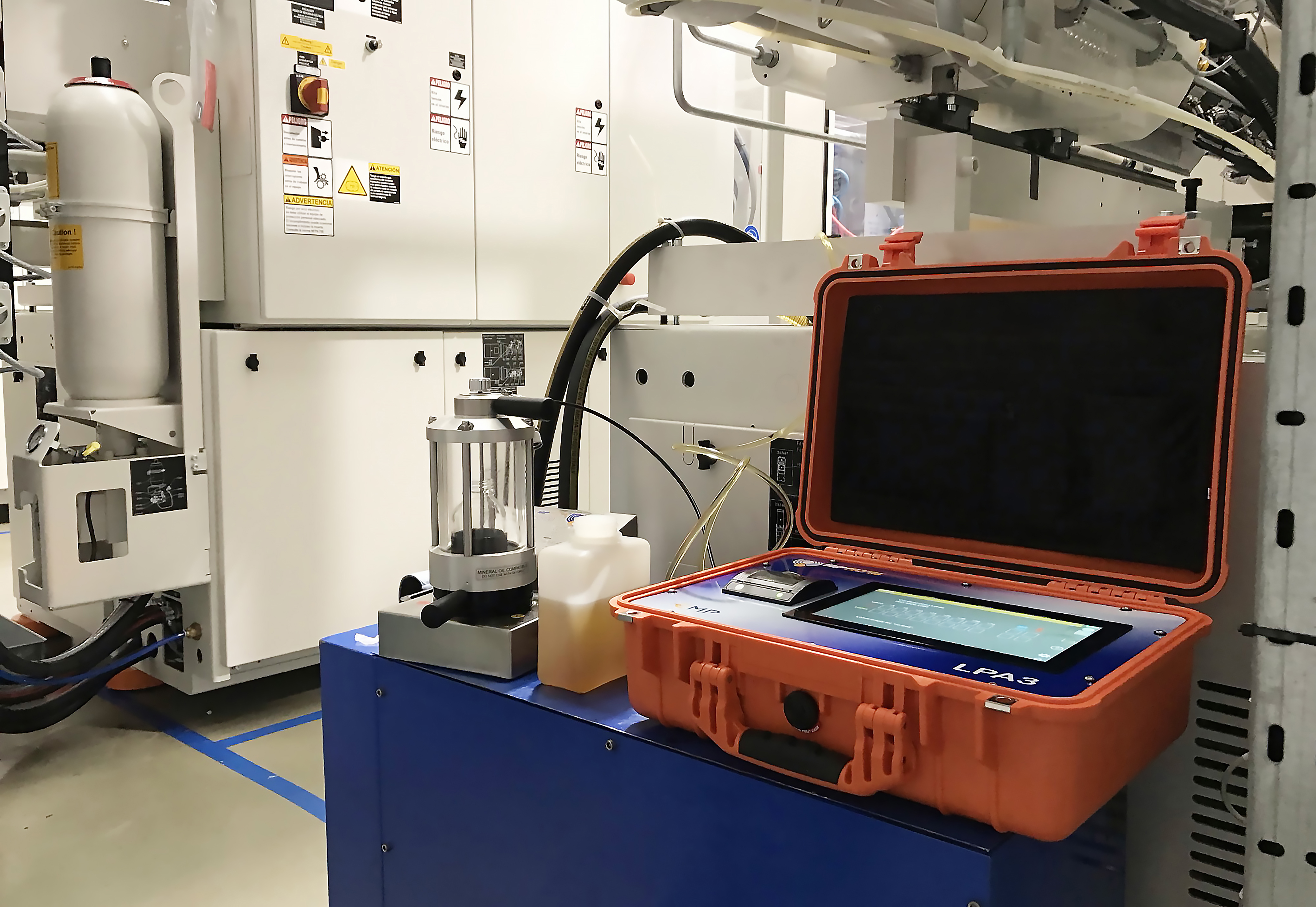

Hydracare found the solution in MP Filtri’s new LPA3, a next-generation portable particle counter which offers a suite of advanced features including real-time monitoring of contamination, live trend analysis, and a comprehensive hydraulic health check to a wide range of international standards.

LPA3 is fully compatible with bottle samplers, stores up to 4,000 test results, and features a fully programmable 10.1” full colour touchscreen display for ease of use. Weighing in at just 10kg it is also fully portable – bringing all the benefits of the laboratory into the field.

Hydracare director Max Ainley revealed he and his team of field service engineers have been delighted with the performance of the LPA3:

He said: “Our new LPA3s increase the efficiency of our operation, save our engineers valuable time and most importantly, enhance and increase the value of service Hydracare offers to our customers.”

Customer Verdict

Max said: “The LPA3 Particle Counters allow our engineers to confidently provide our customers with ‘on the spot’ analysis of oil cleanliness.“

Immediate action can then be taken to remedy concerns, where they are apparent, without the additional expense of a further visit. The units also enable our engineers to confirm the efficacy of filtration before disconnecting equipment and leaving the site.

“The LPA3 is saving our customers money, preventing downtime, and helping them to maintain costly and complex machinery with longer lifespans and lower service and maintenance costs.”

March, 2022

March, 2022